Ball Watches Technology

The Company

The invention or the railroad and its use throughout time is a huge American icon. They not only helped settle America but they unified the country connecting towns and cities in a intricate spiders web of steel and wooden sleepers. For hundreds of people across America predominantly before the further development of the automobile the smokey trail followed by the chuffing furnace of the trains engine was the iconic symbol of freedom and exploration, helping people feel less-isolated in remote parts of the world. Now, it acts as inspiration for Ball Watch Company;

The Mission

Ball Watches have always stuck true to their mission as a brand ever since 1891; “Be yourself; no base imitator of another, but your best self.”

They ask customers to maintain their independence and freedom because life is a journey and not just a destination. To remember that all of life is an experiment and that you should strive to find out who you are through exploring the world. Unless you try to do something beyond what you have already mastered, you will never grow.

They believe that the purpose of life is to be honourable, compassionate, useful and to use these traits to make as much of a difference as you can so that you can look back and know that you have lived and lived well.

Ball Watches challenge you to go forward and make your dreams come true as your greatest glory is not in never failing, but in rising up every time you fail, the brands pushes you to always do what you are afraid to do and finally to dare to live the life you have dreamed for yourself.

Do not go where the path may lead, go instead where there is no path and leave a trail.

At Ball Watch Company are completely and utterly focused on building the mightiest, most superior watches that endure all adverse conditions.

Night Reading Evolution

The power of micro gas tubes (H₃)

The watches hands and hour markers/numbers are lit up by an innovative solution. Ball Watches use Self-Powered Micro Gas Tubes (H₃) which are a groundbreaking new form of light source which is manufactured by Swiss laser technology. They provide unparalleled, durable brightness which is approximately 100 times brighter than any other brand that uses luminous paint on their hands and markers. They also have lifetime which reaches approximately 25 years. The BALL micro gas tubes never need recharging as they do not use the sunlight and they also do not drain batteries. Please note that the brightness of H₃ micro gas lights does eventually deteriorate however this happens over a number of years. This evolution in night reading means that you can always read a BALL watch quickly and under any environment.

How does the technology work?

This new and advanced technology by Ball Watches safely captures tritium gas (H₃) in a very stable form. Tritium gas is well know for its radio luminescence properties, the Pure tritium gas is sealed completely within a tiny hollow mineral glass tubes, these are then coated with a luminescent material that gives off cold light when activated by the electrons that the tritium gas emits. The precise and minute lightweight H₃ gas tubes are accurately manufactured by a CO2 laser. Once manufactured the tubes are attached to the hands and dial securely so that they are not at risk of breakage. It can take a number of these glass tubes to make up one number for example the number ‘2’ comprises of 5 tritium filled tubes, you can see the photos or more information. The wearer can be assured as a complete and intact BALL watch does not come with any exposure risk to the tritium and its irradiation.

SpringLOCK® Patented Anti-Shock System

To enhance watch accuracy

the most common cause of watch inaccuracy is when the balance spring dislodges mostly upon shock impact. SpringLOCK®, is the world’s first BALL’s patented revolutionary anti-shock system which enhances a watches accuracy by reducing balance-spring’s shock impact by an astonishing 66%.

The balance-spring’s dissection

When you take apart the balance spring and its components you start to realise the technology that goes into these watches. The balance-spring is a tiny spring wound up in a concentric circle and attached at each end to the balance and the balance-cock respectively. The balance and balance-cock work together in perfect harmony and constitute a watch’s regulating organ. It is within this organ that the degree of accuracy with which it functions depends. The system regulating this is usually one of the most delicate parts of a watch and usually the one to break when it is exposed to violent impact due to its fragile nature.

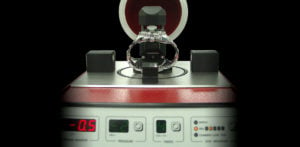

The SpringLOCK® Cage

The SpringLOCK® Cage was exclusively developed by BALL Watch and its purpose was to protect the balance-spring of the watches movement by means of a sturdy cage that limits the unrolling or unfolding of any of the coils in case of any hard knocks or impacts that the watch may suffer within its lifetime of use. It considerably reduced the risk of damage or breakages to the balance-spring’s link, the balance or from any unexpected movements that could deform the shape of the balance-spring itself.

How bad can the shocks be?

External shock impacts are one of the most common causes of internal watch damage and they can cause a number of faults of issues one of which is it can cause standard mechanical movements to fluctuate by up to 60 seconds a day. The SpringLOCK® system dramatically reduces their effect by up to 66 % which ensures that the calibre remains accurate. Ball watch wearers can now freely engage in a whole host of extreme sporting activities including surfing, caving diving to name a few with the reassurance that accurate time keeping can still be possible under external shock impacts.

A-PROOF® Patented Anti-Magnetic System

Just like a human eye

The Ball Watches A-Proof Anti-Magnetic System was developed and patented as a revolutionary approach to the ongoing mission to protect the mechanical movement within the watch against the influence of strong magnetic fields from a number of sources. The technology is based on cutting-edge developments in terms of both construction and the materials used in construction.

The choice of mumetal

BALL Watch carefully selected mumetal for the development of its magnetic trench box located inside the watch’s case. Mumetal is an alloy which comprises of nickel, iron, copper and molybdenum with very high magnetic permeability, it is this magnetic permeability that enables it to attract and deviate static or low-frequency magnetic field lines away from the watch.

The diaphragm mechanism

The constant imprisonment of the movement in an anti-magnetic cage wasn’t something Ball Watches wanted to even consider and the managed to avoid it thanks to an innovative diaphragm mechanism that extends or retracts upon request by a simple circular motion of the bezel. “In the fully closed position, the diaphragm locks the mumetal anti-magnetic protection cage. In the retracted position, the diaphragm therefore re-opens to reveal the movement at work through a transparent case back.” This was a huge feat for Ball Watches and they acted fast to patent this so as to protect it from competitiors. The diaphragm its self is computer aided machined in mumetal with an incredibly precise thickness of just 0.06mm. A-PROOF® protects a mechanical watch against magnetic fields up to an astonishing record intensity of 80,000A / m.

Temperature Measurement (TMT)

Read the temperature on a mechanical thermometer

The BALL TMT movement is able to power the world’s first mechanical thermometer from -35°C to 45°C (-31°F to 113°F) on a wristwatch. The movement powers a spiral bimetallic thermometer to measure temperature with incredible precision which is more than the temperature modules used in previous watches.

The design obstacles

The most difficult challenge Ball Watches faced in the mechanical thermometer (TMT) watch project was keeping the height of the entire movement module to under 5.1mm which is an incredible feat for any watch technician or engineer. The tight coil must fit absolutely perfectly with no errors into the workings of the automatic movement to be able to achieve this. Ball Watches most esteemed watchmakers managed to overcome this design obstacle as they did with many others for example the height and milling of the main plate and bridge.

The mechanism’s prowess

Ball invented a unique system to finely regulate the mechanism using a patented fine regulating screw that doesn’t obstruct the bimetallic blade. The fine regulating screw has two functions firstly it needs to very precisely adjust the temperature indicators position and secondly it needs to be able to hold the bimetallic spiral under any extreme. Once complete Ball thoroughly and rigorously tested the measurement they then monitored its vibrations so that they could learn to control them they then conducted shock tests to guarantee the highest level of shock resistance.

Amortiser® Patented Anti-Shock System

To ensure a better movement’s protection

The Amortiser® patented anti-shock system allows full protection of the mechanical movement within the watch from any damages caused by external shocks. Any moderately large shoch cant cause sudden oscillations of the rotor of any automatic watch that can damage the watches movement sometimes beyond repair and in most other cases the watch is repairable however it is at a very expensive repair cost to the customer.

How to absorb the shocks?

The Amortiser® system absorbs the shocks of external knocks and bumps thanks to its protective and anti-magnetic ring around the mechanical movement that absorbs the energy created by shocks to the watches sides. A switch which looks like a propeller or a submarine on the case back of the watch enables the rotor to be locked and unlocked depending on hat the customer or owner wishes. The ingenious mechanism prevents any energy of hard hitting frontal impacts being transmitted through into the watches delicate movement. When the customer or owners immobilises the rotor the watch can still continue to run by using some or all of the watches reserve power. When the watch is no longer at the risk of knocks the customer or owner can unlock the rotor to bring the automatic winding system ‘back online’ so to speak.

The most robust automatic chronograph

The Engineer Hydrocarbon Spacemaster Orbital II was is fitted with the spectacular Amortiser® system and when tested the watch demonstrated endurance of 5.2 meters of free fall without any damage to the watches mechanical movement, making this timepiece the most robust automatic chronograph that ball currently stock.

Anti-Magnetism

Well thought through anti-magnetic timepieces

Almost all of the BALL watches currently available have incredible anti-magnetic cases which are constructed with corrosion-resistant ferritic stainless steel materials ensuring reliance and durability. Most models also feature a soft iron inner jacket, consisting of a manufactured back plate, a ring surrounding the movement and the dial that ensures protection of the watches inner workings. This specialist alloy that is uses is also reinforced by the shape of the case to prevent magnetic fields from penetrating into the watches movement which would cause adverse effects on the watches accuracy.

The anti-magnetic standard

So what exactly does “anti-magnetic” mean in relation to watches? Is it just marketing jargon? Well the current definition is “An anti-magnetic mechanical watch does not stop when exposed to a magnetic field of 4,800 A/m and subsequently does not deviate by more than 30 seconds per day.”

All of the anti-magnetic timepieces available from Ball Watches more than surpass this standard, particularly the Engineer Hydrocarbon series with 12,000 A/m standard protection.”

Cold Temperature Endurance

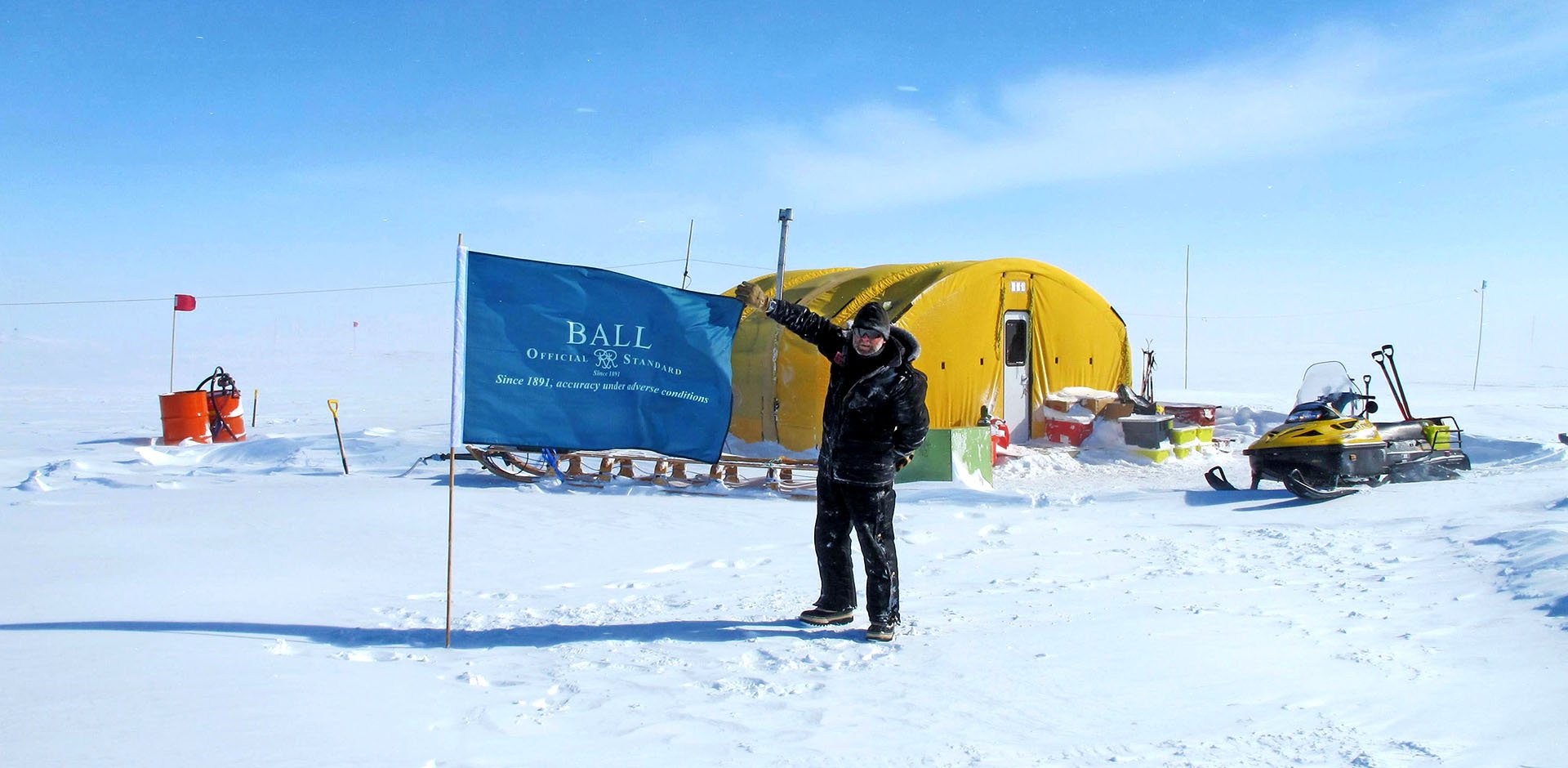

Ready for the North Pole!

Almost all of Ball watches timepieces have a specific blend watch oils developed in Switzerland on them so as to increase the operating temperature range from -40°C to 60°C (-40 to 140°F). This Swiss oil allows these robust timepieces to be a dependable partner for BALL Explorers such as Anthony Powell in his endeavours across the world’s most challenging environments.

The use of movement oil

“Movement oil plays a vital role in every mechanical movement. It acts as a lubricant that reduces the friction between contact surfaces of the different small components. Without the lubricant, the friction created would wear out the movement and adversely affect its accuracy.”

Shock Resistance

Built to be strong

Ball watches pride themselves on being the best, every BALL is built with the highest quality standards in mind. They undergo thorough testing procedures to verify its impeccable shock resistance which is an astonishing 5,000Gs. This test is conducted in compliance with the International Standard ISO 1413 by using a pendulum impact-testing machine. The mechanism revolves in a circular movement with a weighted pendulum at the end which then hits the watch from a precise distance of one meter.

Because it can handle more

With the Engineer Hydrocarbon collection, the basic level of standard is not enough for Ball so they go well beyond by testing with a tougher 1.5 meter hammer strike, raising the resistance to 7,500Gs. They don’t even stop there Ball conduct a further third shock test against three o’clock crown position of the watch which is substantially weaker than any other position these tests their patented crown protection system to ensure the watch functions properly. Almost all Engineer Hydrocarbon watch models can resist this 7,500Gs test without any damage. To put the cherry on the cake so to speak the Engineer Hydrocarbon collection also features a specially made 4mm sapphire crystal for even better protection.

Patented Helium System

The helium release valve

BALL Watches were able to manufacture and integrate a completely automatic helium release valve precisely into the watches crown to allow for the escape of gases as the watch resurfaces from the pulverising pressure of the deep ocean. BALL patented this innovation which has eradicated a potential surface liable to warp under the effects of water pressure, thereby improving the timepiece’s water resistance even further.

Depth pressure

One of the most important requirements of watches when deep-sea diving is for the helium gas to be able to escape. During a divers descent into the unknown they are generally placed in a diving bell where they are exposed to an air that is full of helium. The pressure is also increased very gradually until they reach the depth pressure. The watch is then penetrated by tiny helium molecules. Once the diver is ready to resurface they need to stay in the diving bell for a calculated time in order to be put under the pressure of standard atmospheric levels. Too much internal pressure in the watch caused by the helium molecules that need to escape can cause irreparable damage to the watch.

GMT and World Time Functions

To fulfil the dream of travellers.

Greenwich Mean Time movements provide vital functions to modern day explorers: timing two locations on one wrist. They use a 24-hour second time zone that can be very easily changed depending on the wearer’s location. To make Ball Watches GMT unique and to enhance the readability further the second time zone display has incorporated our Swiss micro gas light tubes. Most of our GMT collections feature the world’s only selfilluminated second time zone, not only the hour hand, but also the hour itself is traced across the dial.

Be aware of the time everywhere in the world

Ball Watches wanted to be able to provide its customers with watches that are able to operate in all corner of the globe to do this they introduced the world’s first mechanical movement including a day and date function combined with a 24-hour time zone display. This mechanical movement was crafted in the Ball Watches workshops where the technicians works tirelessly on creating a a standard caliber with an additional worldtime module drives a disk engraved with the names of the world’s main metropolises rotating automatically in the reverse direction to the hands to simultaneously indicate the time in 24 different geographic zones.

Slide Chronograph

A new way to record time

The standard button chronograph feature has been completely reinvented y Ball Watches, in their innovative new design the have combined the two push button model in one integrated control at 9 o’clock on the case. The Slide Chronograph system includes a circular slide bar fitted around the movement. The chronograph is started and stopped with a clockwise rotation of this slide bar, which then returns automatically to its original position, while an anticlockwise movement resets the chronograph feature.

Better ergonomics and control

Developed and patented by Ball Watches, the Slide Chronograph features a whole host of ergonomic improvements, both essential factors in the accuracy and speed of a chronograph function. The chronograph can therefore be guided easily with one finger while still wearing the watch making it a lot easier to use. The stylish look of the mechanism brings a better quality of user experience to the mechanical timepiece.

Patented Folding Buckle

Great resistance and extreme comfort

Ball Watches created a patented triple folding buckle with extension performs with several assets. The groundbreaking buckle is manufactured from a single block of stainless steel for even better strength, wear resistance and long lasting quality. The balance of the clasp is perfect it folds smoothly and all of the buckles elements are equally divided under the buckle cover. It also stretches to a 22mm extension system on both sides of the bracelet allows an ergonomic fit on most common types of sportswear.

The buckle’s features

The buckle and the extension can be opened with one hand making it easy to put on and take off under a range of conditions. The closure works with a mechanical lock which resists powerful traction forces.

Water Resistance

To discover the depths

The water resistance of Ball Watches varies but only by collection so if one of a collection is water resistant all of the watches in that collection will be. For example the Trainmaster and Conductor series begin at 30m/100ft. The Engineer II and Fireman series are 100m/330ft. The Engineer Master II series ranges from 100m/330ft to 300m/1,000ft. And finally, the Engineer Hydrocarbon series begins at 300m/1,000ft and goes up to 3,000m/ 9,850ft for the DeepQUEST.

How to test water resistance?

Water resistance is tested by immersing the watch completely in distilled water containing a wetting agent of 1% by weight and under the prescribed atmospheric pressure for at least five minutes. To be qualified, the watch must show no evidence of water leakage at all.

Crown Protection System

For superior water and shock resistance

The patented crown protection system ensures water and shock resistance like no other, even at the most vulnerable area of the case, the crown. Many watches are damaged due to water leakage or external shock damages occurring from or next to the watches crown. The crown is amongt one of the most at risk parts of a watch especially if it is not a screw-down crown.

A crown protection developed for the Engineer Hydrocarbon series

A special crown protection system was designed for the Engineer Hydrocarbon series to guarantee its exceptional water resistance. A protective plate is placed around the crown, which ensures the crown must be screwed-in to its original secure position after time adjustment. The shock resistance test conducted on Engineer Hydrocarbon models also tests the crown protector to ensure it will prevent damage to the crown and resist water leakage as well. The crown is tested with external shocks to ensure its durability up to 7,500Gs.

You can continue to learn about this fantastic brand by reading all about the history, and the inspiration of American Railroads by reading our fantastic post here.